Height rank

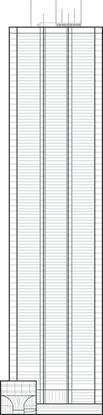

MLC Centre

Sydney

- CTBUH Drawing

- Facts

-

Metrics

You must be a CTBUH Member to view this resource.

To Tip:

Height is measured from the level of the lowest, significant, open-air, pedestrian entrance to the highest point of the building, irrespective of material or function of the highest element (i.e., including antennae, flagpoles, signage and other functional-technical equipment).Architectural:

Height is measured from the level of the lowest, significant, open-air, pedestrian entrance to the architectural top of the building, including spires, but not including antennae, signage, flag poles or other functional-technical equipment. This measurement is the most widely utilized and is employed to define the Council on Tall Buildings and Urban Habitat (CTBUH) rankings of the "World's Tallest Buildings."

Above Ground

The number of floors above ground should include the ground floor level and be the number of main floors above ground, including any significant mezzanine floors and major mechanical plant floors. Mechanical mezzanines should not be included if they have a significantly smaller floor area than the major floors below. Similarly, mechanical penthouses or plant rooms protruding above the general roof area should not be counted. Note: CTBUH floor counts may differ from published accounts, as it is common in some regions of the world for certain floor levels not to be included (e.g., the level 4, 14, 24, etc. in Hong Kong).Below Ground

The number of floors below ground should include all major floors located below the ground floor level.Official Name

MLC Centre

Type

Building

Status

Completed

Completion

1977

Country

City

Address

Function

A mixed-use tall building contains two or more functions (or uses), where each of the functions occupy a significant proportion of the tower's total space. Support areas such as car parks and mechanical plant space do not constitute mixed-use functions. Functions are denoted on CTBUH "Tallest Building" lists in descending order, e.g., "hotel/office" indicates hotel function above office function.

Office

Structural Material

Both the main vertical/lateral structural elements and the floor spanning systems are constructed from steel. Note that a building of steel construction with a floor system of concrete planks or concrete slab on top of steel beams is still considered an “all-steel” structure as the concrete elements are not acting as the primary structure.

All-Concrete

Both the main vertical/lateral structural elements and the floor spanning systems are constructed from concrete which has been cast in place and utilizes steel reinforcement bars and/or steel reinforced concrete which has been precast as individual components and assembled together on-site.

All-Timber

Both the main vertical/lateral structural elements and the floor spanning systems are constructed from timber. An all-timber structure may include the use of localized non-timber connections between timber elements. Note that a building of timber construction with a floor system of concrete planks or concrete slab on top of timber beams is still considered an “all-timber” structure as the concrete elements are not acting as the primary structure.

Mixed-Structure

Utilizes distinct systems (e.g. all-steel, all-concrete, all-timber), one on top of the other. For example, a Steel Over Concrete indicates an all-steel structural system located on top of an all-concrete structural system, with the opposite true of Concrete Over Steel.

Composite

A combination of materials (e.g. steel, concrete, timber) are used together in the main structural elements. Examples include buildings which utilize: steel columns with a floor system of reinforced concrete beams; a steel frame system with a concrete core; concrete-encased steel columns; concrete-filled steel tubes; etc. Where known, the CTBUH database breaks out the materials used within a composite building’s primary structural elements.

All-Concrete

Height

228 m / 748 ft

Floors Above Ground

60

Floors Below Ground

8

# of Elevators

33

Top Elevator Speed

7 m/s

Tower GFA

100,000 m² / 1,076,391 ft²

Rankings

-

By function

You must be a CTBUH Member to view this resource.

-

By material

You must be a CTBUH Member to view this resource.

Construction Schedule

Construction Start

Completed

Contractor

The main contractor is the supervisory contractor of all construction work on a project, management of sub-contractors and vendors, etc. May be referred to as "Construction Manager," however, for consistency CTBUH uses the term "Main Contractor" exclusively.

Material Supplier

Material Supplier refers to organizations which supplied significant systems/materials for a building project (e.g. elevator suppliers, facade suppliers, etc).

Material Supplier refers to organizations which supplied significant systems/materials for a building project (e.g. elevator suppliers, facade suppliers, etc).

You must be a CTBUH Member to view this resource.

Architect

Usually involved in the front end design, with a "typical" condition being that of a leadership role through either Schematic Design or Design Development, and then a monitoring role through the CD and CA phases.

Harry Seidler and Associates

Contractor

The main contractor is the supervisory contractor of all construction work on a project, management of sub-contractors and vendors, etc. May be referred to as "Construction Manager," however, for consistency CTBUH uses the term "Main Contractor" exclusively.

Material Supplier

Material Supplier refers to organizations which supplied significant systems/materials for a building project (e.g. elevator suppliers, facade suppliers, etc).

Material Supplier refers to organizations which supplied significant systems/materials for a building project (e.g. elevator suppliers, facade suppliers, etc).

CTBUH Initiatives

Warm Weather Spaces Walking Tours 2015

17 September 2015 - Event

Videos

19 September 2012 | Sydney

Retrofit and Refurbishment of Existing Tall Buildings

Existing buildings are a city’s heritage, skyline, and contribute to its distinct character. They also represent a considerable spent investment in terms of both material...

About MLC Centre

Australia’s tallest building and the second tallest concrete building in the world upon completion, MLC Centre was conceived with a number of design features which were initially developed for construction of Australia Square. The MLC Centre, like Australia square is set back on a plaza, with the tower’s non-rectilinear footprint occupying only 20 percent of the entire site area. By placing the tower on the southern end of the site, the building could avoid an underground railway while also providing for an outdoor public plaza best positioned to receive natural sunlight.

The MLC Centre is octagonal in form, based on a square plan aligned diagonally to street grid and then chamfering the corners. The form provided for a footplate with a larger area than a typical rectilinear building, but more efficient spatially with interiors having better access to natural light and views, while also reducing the amount of wind loading on the overall tower. Like Australia Square, MLC Centre utilizes a series of tapering large external columns surrounding the building’s perimeter, except here the columns tapper completely until they become flush with façade at the top of the building. Also like Australia Square, the construction process utilized quartz concrete set into pre-cast units of standardized sizes and used not only as a finish of the exterior façade, but also as formwork for the pouring of the reinforced concrete structure, assisting in shorting the construction schedule as the building rose at an average rate of one floor every four days. The façade was then composed of recessed windows and textured concrete spandrels provided for passive solar shading. After completion, MLC Centre held the title of Australia’s tallest building for nine years, until it was surpassed by the Rialto Towers in Melbourne.

Subscribe below to receive periodic updates from CTBUH on the latest Tall Building and Urban news and CTBUH initiatives, including our monthly newsletter. Fields with a red asterisk (*) next to them are required.

View our privacy policy